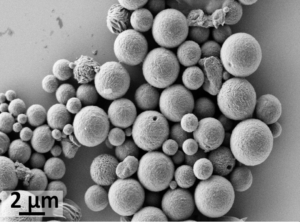

The aim of this project is the production of novel polymer particle systems for additive manufacturing processes by applying wet grinding and melt emulsification with integrated surface functionalization. Within the second funding period, the aforementioned processes will be expanded towards filled polymer systems and blends. Furthermore, the energy consumption will be characterized and optimized. Polymer particle systems for the use in the beam melting process (particle size 5 – 20 µm) are obtained by spray drying and spray agglomeration (e.g. composite particles) of the produced product suspensions. These particles with optimized flowability and advantageous packing properties will substantially expand the availability of polymer powder materials for additive manufacturing processes.

For more details see the SFB 814 website.